- This topic is empty.

-

AuthorPosts

-

03/01/2025 at 17:58 #78589

Wind energy has emerged as one of the most viable and sustainable renewable energy sources, leading the global charge toward decarbonization. Advanced transmission and load management systems are crucial to harness the full potential of wind power. At the heart of these systems lies the wind power planet carrier—a critical, yet often overlooked, component that ensures wind energy is efficiently transmitted and utilized. In this article, Tianshan delves deep into the role of wind power planet carriers, highlighting their indispensable role in wind turbine systems.

What are Wind Power Planet Carriers?

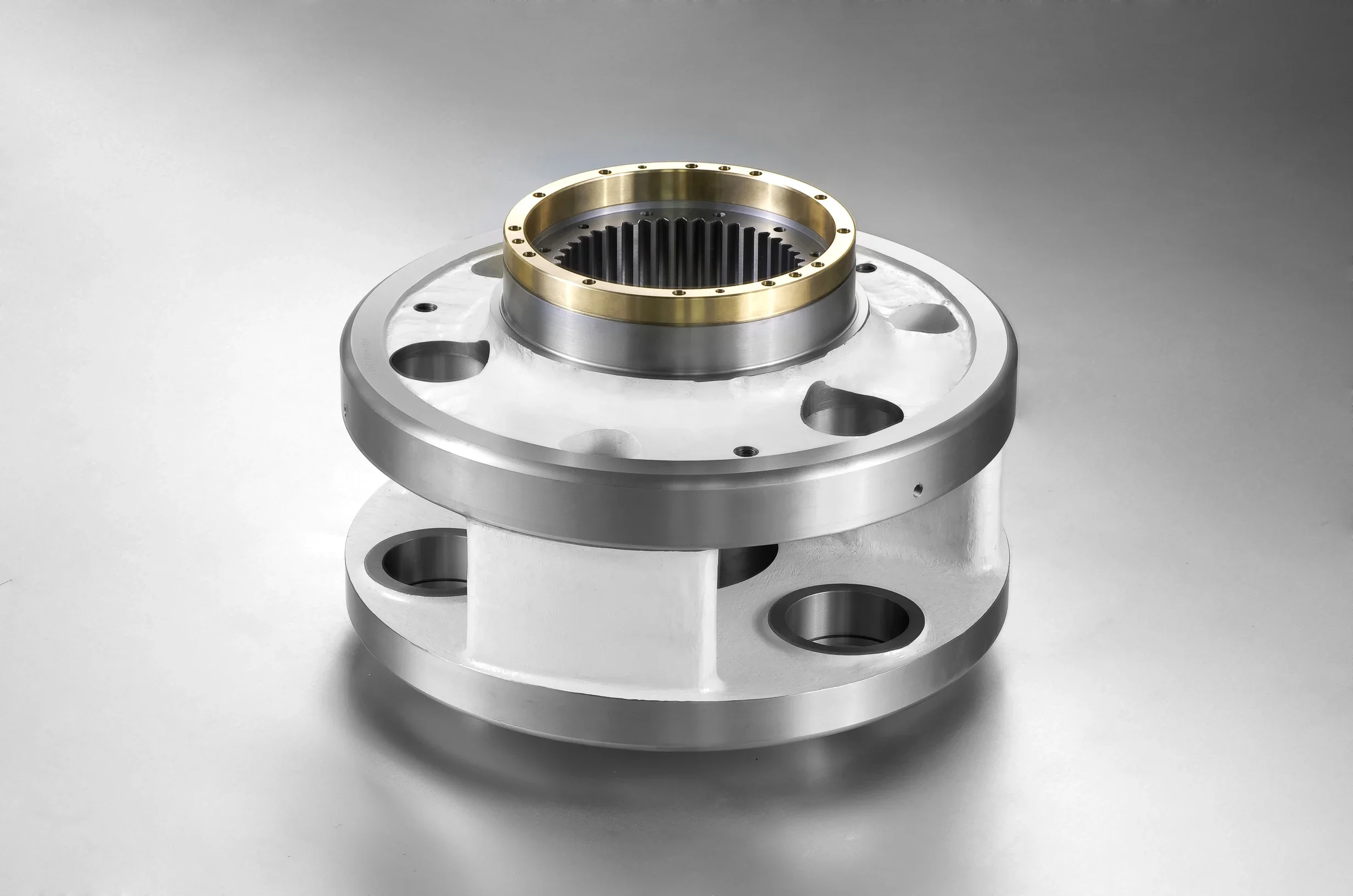

A wind power planet carrier is a central component of the planetary gearbox system used in wind turbines. The primary role of a wind power planet carrier is to support and house the planetary gears, which convert the relatively low rotational speed of the wind turbine blades into the high-speed rotation required to drive the generator. This component is engineered to endure extreme mechanical loads, ensuring reliability and durability in demanding operational environments. Planetary gear systems are preferred in wind turbines because they are compact, efficient, and capable of transmitting high torque loads. The wind power planet carrier sits at the center of this system, aligning and stabilizing the planetary gears while maintaining the precision required for optimal power transmission. Its structural integrity and design directly influence the overall performance and efficiency of the wind turbine.

The Role of Wind Power Planet Carriers in Offshore Wind Farms

Offshore wind farms play a vital role in the global push toward renewable energy, capitalizing on stronger and more consistent wind resources found in marine environments. These installations are pivotal in reducing greenhouse gas emissions and transitioning toward a sustainable energy future. However, the unique challenges posed by the offshore setting, such as corrosive saltwater, strong winds, and high mechanical stresses, necessitate specialized engineering solutions for critical wind turbine components. Among these components, the wind power planet carrier is of particular significance, as it is essential for the proper functioning and durability of wind turbine gearboxes.

The wind power planet carrier operates as a core element in the gearbox of a wind turbine, transferring torque efficiently and reliably under significant mechanical loads. Offshore wind turbines, being larger and more powerful than their onshore counterparts, demand even greater performance from their planet carriers. The marine environment subjects these components to extreme conditions, including constant exposure to salt-laden air, high humidity, and fluctuating temperatures. These factors increase the risk of material degradation, corrosion, and fatigue, which could compromise the long-term operation of the turbine.

To address these challenges, modern wind power planet carriers are designed with a focus on corrosion resistance and enhanced durability. Advanced materials, such as high-strength alloys and composite coatings, are employed to protect against the aggressive marine environment. Anti-corrosion coatings, often incorporating innovative technologies like thermal spraying or polymer-based solutions, form a robust barrier that shields the carrier from the effects of salt and moisture. These coatings not only extend the lifespan of the component but also reduce the need for frequent maintenance, thereby lowering operational costs and downtime.

Furthermore, the design and manufacturing processes for wind power planet carriers have evolved to accommodate the increasing size and capacity of offshore wind turbines. Finite element analysis and advanced simulation techniques are utilized to optimize the geometry of the carrier, ensuring that it can handle higher torque loads without excessive weight or material usage. Precision machining and stringent quality control measures are also integral to producing components that can meet the rigorous demands of offshore operations.

The reliable performance of the wind power planet carrier is crucial for the cost-effectiveness and sustainability of offshore wind farms. As these projects typically involve significant upfront investment and operate in remote locations, minimizing maintenance requirements and maximizing turbine availability are essential for their economic viability. By combining cutting-edge materials, innovative design strategies, and robust manufacturing techniques, modern wind power planet carriers contribute significantly to the efficiency and resilience of offshore wind turbines.

Wind power planet carriers are more than just mechanical components; they are the backbone of wind energy systems, enabling the efficient and reliable harnessing of wind power. From torque conversion to load distribution, these carriers play a pivotal role in ensuring the performance and longevity of wind turbines. As wind energy continues to expand its share of the global energy mix, the importance of advanced and innovative wind power planet carriers will only grow. With ongoing advancements in materials, design, and manufacturing processes, these components are poised to drive the next generation of wind energy systems, bringing us closer to a sustainable, low-carbon future.

https://www.tianshangear.com/Wind-power-gear-1-5MW-16MW.html

http://www.tianshangear.com

Changzhou Tianshan Heavy Industry Machinery Co., Ltd. -

AuthorPosts

- You must be logged in to reply to this topic.