- This topic is empty.

-

AuthorPosts

-

05/06/2025 at 17:20 #79454

In today’s increasingly industrialized and environmentally conscious world, air pollution control has become a critical issue. One of the key technologies in managing airborne pollutants—especially from industrial emissions—is the use of dry chemical filter media. These advanced filter materials are vital for capturing and neutralizing harmful gases, odors, and particulates before they are released into the atmosphere.

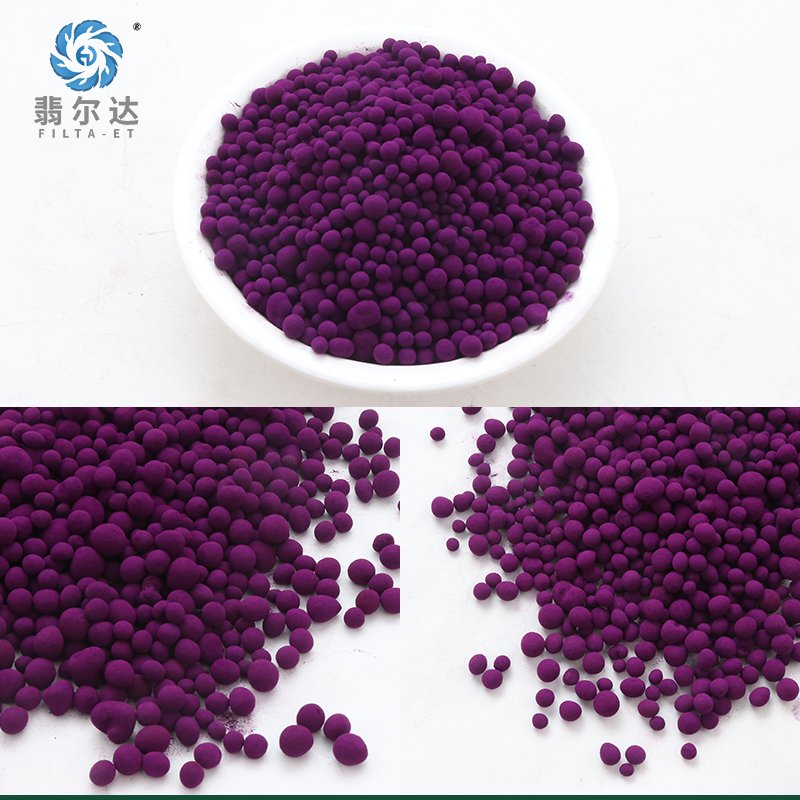

Among the leading innovators in this field is Feierda, a professional company dedicated to the research, development, production, and sales of environmental filter media. With cutting-edge expertise and a commitment to sustainable solutions, Feierda continues to provide high-performance filter media for a cleaner and safer world.

What Is Dry Chemical Filter Media?

Dry chemical filter media are specially engineered materials designed to absorb, adsorb, or chemically neutralize airborne pollutants without the use of water or liquids. These media are typically used in dry scrubbing systems, gas-phase filtration, and odor control applications across industries such as waste treatment, chemical processing, pharmaceuticals, and public utilities.

They often come in granular or pelletized forms, and are packed into filter beds or cartridges, depending on the application.

How It Works: The Science Behind the Filtration

Dry chemical filter media operate through one or more of the following mechanisms:

1. Adsorption

Certain gases—such as volatile organic compounds (VOCs) and sulfur-based gases—are physically adsorbed onto the surface of porous materials like activated carbon or alumina. These materials have high surface areas, enabling them to trap large quantities of pollutants on their microscopic surfaces.

2. Absorption

Some filter media absorb gaseous pollutants by allowing them to diffuse into their structure, where they are held or transformed. This method is effective for water-soluble gases like ammonia and formaldehyde.

3. Chemical Reaction (Chemisorption)

Perhaps the most powerful mechanism, chemisorption involves an actual chemical reaction between the gas molecules and the active ingredients in the filter media. For example, potassium permanganate reacts with hydrogen sulfide (H₂S), sulfur dioxide (SO₂), or formaldehyde to convert them into non-toxic solid byproducts like salts or oxides.

Feierda offers filter media that integrate multiple mechanisms, ensuring broad-spectrum protection against various types of contaminants.

Key Components of Dry Chemical Filter Media

Feierda’s filter media are developed using carefully selected materials, each tailored to specific filtration needs:

Activated Carbon: Ideal for VOCs, benzene, and hydrocarbons through physical adsorption.

Potassium Permanganate-Impregnated Alumina: For oxidizing acidic or odorous gases like SO₂ and H₂S.

Sodium Bicarbonate-Based Media: For neutralizing acidic gases via chemical reaction.

Blended Media: Combining several types for multi-contaminant removal in a single filtration system.

Each of these components is engineered to maximize contact time and reactivity, ensuring efficient pollutant removal and long service life.

Applications Across Industries

Dry chemical filter media are widely used in:

Wastewater treatment plants – for controlling odors and corrosive gases.

Chemical manufacturing – to manage toxic process gases.

Data centers – where airborne contaminants can damage sensitive electronics.

Public facilities – including hospitals, museums, and transportation hubs, to ensure clean indoor air.

Pharmaceutical production – requiring cleanroom conditions and odor elimination.

Feierda’s custom-formulated solutions ensure that customers get the optimal filter media for their unique environmental challenges.

Advantages of Dry Chemical Filter Media

✅ Waterless Operation: Ideal for environments where wet scrubbing is impractical.

✅ Low Maintenance: Media are easy to replace and require minimal system downtime.

✅ High Efficiency: Removes a wide range of pollutants including acidic, basic, and organic gases.

✅ Cost-Effective: Long lifespan and operational simplicity lead to lower lifecycle costs.

✅ Environmentally Friendly: Many media are non-toxic and safe to handle.

Feierda’s products are developed with sustainability, performance, and reliability in mind, offering a trusted solution for demanding filtration needs.

Conclusion

As industries expand and environmental regulations tighten, advanced air filtration solutions are no longer optional—they are essential. Dry chemical filter media offer a powerful, efficient, and eco-friendly way to neutralize pollutants and safeguard both people and equipment.

With years of technical experience and a strong focus on innovation, Feierda stands as a trusted partner in environmental protection. Their comprehensive range of filter media helps industries meet emission standards, improve workplace safety, and contribute to a cleaner future.

Whether you are managing a waste treatment plant, operating a high-tech manufacturing facility, or ensuring clean air in public infrastructure, Feierda has the solution you need.

Top 7 Applications of Dry Chemical Filter Media in Industrial Filtration

http://www.filta-et.net

Feierda Environmental Technology (Zhenjiang) Co., Ltd. -

AuthorPosts

- You must be logged in to reply to this topic.