- This topic is empty.

-

AuthorPosts

-

14/04/2025 at 14:25 #79161

As the global manufacturing industry moves towards intelligence and efficiency, the 3C electronics industry, as a representative of technology-intensive and highly competitive markets, faces a complex production environment with fast product updates, frequent order changes, and small batches of multiple varieties. Traditional fixed production lines can no longer meet the flexibility, rapid response and high quality requirements of modern 3C electronic products. Against this background, flexible automation system came into being and quickly became a key technical support for promoting the upgrading of 3C electronic manufacturing. This article will deeply analyze the application scenarios, advantages, core technologies and development prospects of flexible automation system in the 3C electronics industry to help industry practitioners better understand and apply this advanced system.

1. What is flexible automation system?

Flexible automation system refers to an automated manufacturing system that can adapt to a variety of product specifications, quickly switch production tasks, and has highly configurable and intelligent scheduling capabilities. It integrates modular design, programmable control, industrial robots, sensors, industrial Internet of Things (IIoT), and other technologies, and can complete the assembly, testing, and packaging processes of multiple products without replacing a large amount of hardware.

2. Industry characteristics and challenges of 3C electronic manufacturing

3C electronic products have the following significant manufacturing characteristics: a wide variety of products and fast updates, such as mobile phones, tablets, smart watches, etc., with many models and short life cycles.

Fast production rhythm and complex process: most involve dozens or even hundreds of process links.

High dependence on labor and large quality fluctuations: Some companies still rely on traditional manual assembly, testing, and handling.

Increasing demand for personalized customization: Consumers have stronger demand for personalized product appearance and functions.

Faced with these challenges, the shortcomings of traditional automation equipment, such as "difficult line change, slow debugging, and low compatibility," have become increasingly obvious, seriously restricting the company's production efficiency and flexibility in responding to the market. At this time, the emergence of flexible automation systems provides a new solution.

3. Advantages of flexible automation system

Quick line change, more agile response to the market: traditional automation lines often take hours or even days to change lines, while flexible systems only need to adjust parameters or replace a small number of modules to complete production switching, significantly shortening the delivery cycle.

Compatible with multiple products and improve equipment utilization: One system can be compatible with multiple product models, greatly improving the return on investment (ROI) of equipment and effectively coping with the "multi-product small batch" order structure.

Reduce manual dependence and stabilize product quality: Through standardized operations and intelligent control, the system can run stably 24 hours a day, effectively reducing manual errors and fluctuations, and improving product consistency and yield rate.

Data-driven production and support for intelligent decision-making: The system supports real-time data collection and analysis, can monitor equipment status, production line efficiency, and quality trends, provide management with decision-making basis, and promote lean production.

With scalability and upgradeability: As products change and enterprises develop, the system can add robots, workstations, sensors, etc., as needed to achieve flexible expansion without replacing the entire system.

4. Application scenarios

In the 3C electronics industry, the application of flexible automation system can cover multiple key links, including:

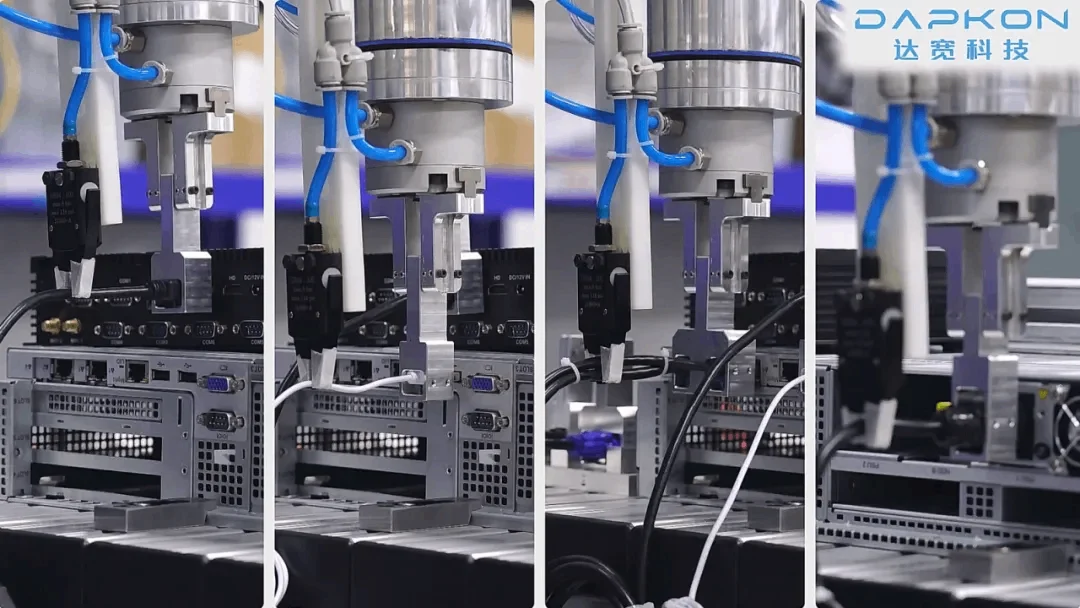

Automated assembly system: Through robot collaboration units, combined with visual recognition and force control technology, high-precision assembly of small precision components (such as chips, camera modules, and batteries) can be achieved. The system can automatically switch assembly routes and fixtures according to order requirements, greatly improving line change speed and equipment utilization.

Flexible inspection system: With the help of machine vision and AI algorithms, the size, appearance, and function of various products can be quickly inspected. The system can automatically adjust the inspection parameters to avoid repeated programming, which is suitable for parallel inspection of multiple varieties.

Automated test unit: For different functional tests (such as key sensitivity, touch response, battery charging, etc.), the flexible test platform can achieve "plug and test" and support rapid adaptation of multiple interface protocols.

Flexible logistics and handling system: AGV (automatic guided vehicle) and RGV (rail-guided vehicle) are combined with an intelligent scheduling system to realize dynamic distribution and transportation of materials between production lines, improve logistics efficiency, and reduce manual intervention.

Flexible packaging and palletizing system: The system can automatically adjust the packaging module according to different product sizes and packaging methods, realize one-click switching of packaging specifications, and adapt to the mixed flow processing of multiple orders.

Flexible automation system is becoming a key fulcrum for the 3C electronics industry to move towards intelligent manufacturing. It not only brings significant improvements in production efficiency and product quality, but also shows strong adaptability in meeting diverse and rapidly changing market demands. In the future, with the integration and development of cutting-edge technologies such as AI, IoT, and 5G, flexible automation systems will play an increasingly important role in the 3C electronics field, helping companies build a more competitive smart manufacturing ecosystem.

As a professional flexible assembly company, we are committed to providing 3C electronics manufacturers with highly flexible and modular smart assembly technology, helping customers achieve fast line change, efficient production, and intelligent upgrades.

http://www.dapkon.ai

Shanghai Dapkon Technology Co., Ltd. -

AuthorPosts

- You must be logged in to reply to this topic.