- This topic is empty.

-

AuthorPosts

-

30/12/2025 at 18:12 #80782

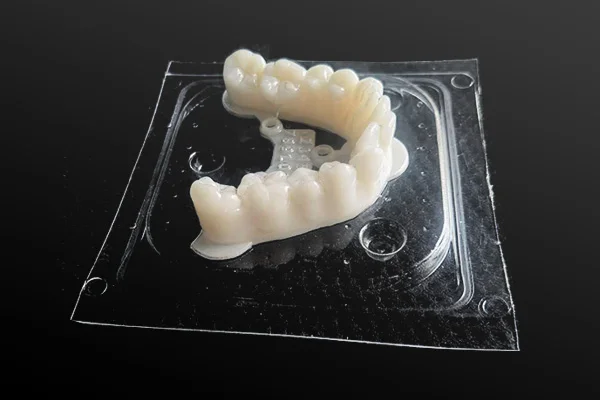

In the dynamic world of orthodontics, the shift toward clear aligners has redefined both patient expectations and manufacturing standards. As more clinics and labs produce clear aligners in-house or for export, the pressure to optimize production—while maintaining clinical quality—has never been higher. Enter the era of full-workflow automation, where one machine links multiple steps—from film cutting,thermoforming to robotic trimming—into a seamless, intelligent process.

Among these innovations, ConverSight’s All-in-One Automated Clear Aligner Machine (film roll) HBL-YTJ-01 stands as a milestone: it integrates automated film cutting, model feeding, thermoforming with high-pressure adaptability, and millimetre-level robotic trimming into one compact unit.

In this article, we explore how this machine addresses critical manufacturing pain-points, the technical features that make it stand out, how it fits into modern aligner workflows, and why it matters for manufacturers aiming for real-world scalability and consistency.

Why Automation Matters in Aligner Production

Clear aligner manufacturing involves multiple steps—starting from the raw film material, through thermoforming, trimming, marking, quality control, and packaging. Traditionally, each step is either semi-automated or manual, and each hand-off introduces potential delays, inconsistencies, or defects.

Key challenges:

Manual handling of film rolls or sheets may lead to mis-cuts, waste, or uneven feed.

Variation in thermoforming pressure or temperature profiles, resulting in inconsistent aligners.

Manual or semi-automatic trimming that depends heavily on skilled labour, introducing variability in patient comfort and fit.

Multiple separate machines that increase footprint, cost, maintenance, and line complexity.

By integrating these steps within a single automated solution, manufacturers can reduce manual intervention, optimize material usage, maintain tighter tolerances, and simplify the production line footprint. The commitment of ConverSight is to deliver “full-workflow automation from film roll to finished aligners” with reduced manual input.

Technical Features of the All-in-One Machine

Let’s break down what the automated all in one machine can bring to you based on its technical features:

1. Automatic Film Cutting & Full-Workflow Automation

The system includes an automatic film-cutting module, enabling a closed loop from film roll to finished aligner without manual cut and load. This eliminates the errors caused by manual and optimizes throughput.

2. Automatic Teeth Mold Feeding

The machine accommodates multiple mould-boxes (for example “four boxes of teeth molds”) that can be fed automatically. With visual recognition and precise positioning on tooling, the machine runs continuously for extended periods with minimal supervision.

3. High-Pressure Thermoforming

The thermoforming module supports high-fitting pressure, ensuring the film material is evenly heated and softened across its surface. Temperature ranges (up to high values) and pressure are adjustable to produce a clear aligner prototype matching digital design contours, delivering superior fit and clarity.

4. Millimetre-Level Precision Robotic Trimming

Edge finishing is handled by a high-precision 6-axis robot (for example an ABB robot). It executes trimming of complex, irregular or curved aligners with millimetre-level synchronous control, ensuring each product has smooth edges, consistent shape, and ready-to-use quality.

5. Compact and Integrated Design

Because so many functions are integrated — film cutting, mold feeding, forming, trimming — the footprint is reduced compared to multiple discrete machines. This makes the solution suitable for mid-size labs or manufacturers seeking intelligent production without sprawling complete line setups.

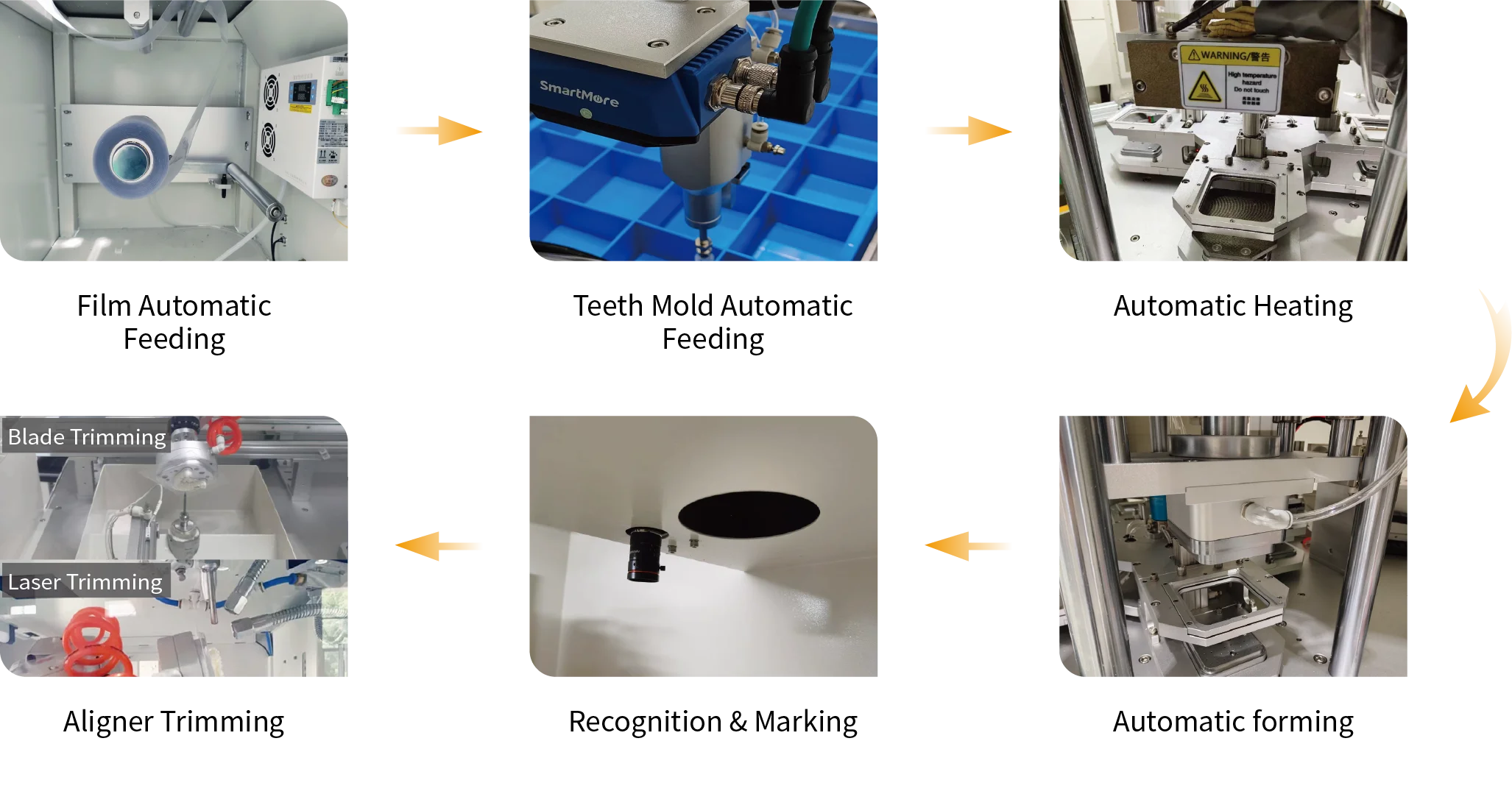

How It Works: From Film Roll to Finished Aligner

Here’s a simplified workflow:

A film roll is loaded into the film-cutting module. The machine slices it into sheets sized and prepared for heating forming.

The automatic mold-feeding unit loads dental models onto the forming station; visual recognition ensures correct positioning.

The thermoforming unit activates, heating and softening the film and applying high pressure to produce the aligner shell.

Once formed, the shell moves (via conveyor) to the marking station for engravings of serial number and logo on the aligner.

Flow to the robotic trimming station, where the 6-axis robot performs the cutting and finishing operations with precision.

The finished aligners emerge from the machine, ready for polishing, cleaning and inspection,etc.

By collapsing many separate stages into one machine, the workflow becomes smoother, less error-prone, and more controllable.

Benefits for Manufacturers & Labs

By adopting the All-in-One machine,dental labs and manufacturers gain:

Reduced manual labour: fewer manual steps mean fewer operators needed and less human error.

Improved material usage: automatic film cutting plus high precision forming reduce material waste and help control costs.

Consistent product quality: robotic trimming and high-pressure forming ensure each aligner matches its digital design and meets patient-comfort standards.

Compact footprint: one integrated machine replaces multiple discrete pieces of equipment, simplifying layout and maintenance.

Scalable adoption: suitable for labs that want to move from semi-automated to fully automated production without building enormous lines.

In an environment where patient expectations for comfort, aesthetics and turnaround time keep increasing, these benefits can keep aligner manufacturers competitive on the market.

Real-World Application & Industry Context

Orthodontic labs today face a dual challenge: increasing demand for clear aligners as consumers prefer aesthetic solutions; and requirement for faster turnaround, higher quality, and lower cost per aligner.

Integration of machines such as the HBL-YTJ-01 enables manufacturers to meet these pressures. For example, when manual cutting and shaping cause delays or inconsistent fit, a unified machine automates all steps and locks in repeatable outstanding quality.

According to industry commentary, full-workflow automated machines that combine forming, trimming and feeding modules are increasingly seen as the future standard for dental labs aiming to scale smartly. The all in one solution from ConverSight is ready to keep you in line with these expectations.

Key Considerations When Selecting an Automatic Clear Aligner Solution

When evaluating a machine like this, manufacturers should consider:

Film compatibility: Does the machine support different film thicknesses, roll vs sheet, multiple brands?

Forming pressure & heat control: High-fitting pressure and heating evenness are critical for aligner fit.

Robot trimming precision: The robot system must handle curved and irregular shapes reliably.

Automation of model feeding: How many molds can be loaded unattended? What’s the visual recognition capability?

Maintenance & services: Integrated machines combine many modules — maintenance strategy is important.

Future scalability: Can the machine allow adding other modules later?

Data & traceability: Does the machine support digital data capture, production logs, and integration with other modules (such as laser marking or inspection)?

Positive answers from these questions will help dental labs avoid selecting the automated equipment that soon becomes a bottleneck.

The Future of Aligner Workflow

The trend is clear: as clear aligner volumes rise globally, automation becomes the baseline. Machines that combine film cutting, thermoforming, and robotic trimming reduce cost per unit, minimize human dependency, and increase production flexibility.

With solutions like the All-in-One machine, manufacturers are able to have smarter production workflows, meet patient expectations faster, and maintain consistent quality even as they scale. The digital transformation in orthodontic manufacturing isn’t just about robotics—it’s about integrated workflows, data-driven controls, and modular flexibility.

Conclusion

The era of disconnected machines and fragmented workflows is ending. For labs and manufacturers ready to obtain a higher market share, the All-in-One Automated Clear Aligner Machine HBL-YTJ-01 delivers a compelling value proposition: one compact machine, multiple modules, no manual steps, and higher consistency.

If you’re seeking a solution that brings film roll cutting, high-pressure thermoforming, automatic model handling, and precision robotic trimming into one integrated unit, this machine represents a strong strategic step toward future-ready aligner manufacturing.

Explore the machine and its specifications in detail here: All-in-One Automated Clear Aligner Machine HBL-YTJ-01

http://www.conversighttech.com

ConverSight Technology Limited -

AuthorPosts

- You must be logged in to reply to this topic.