- This topic is empty.

-

AuthorPosts

-

07/11/2025 at 15:07 #80446

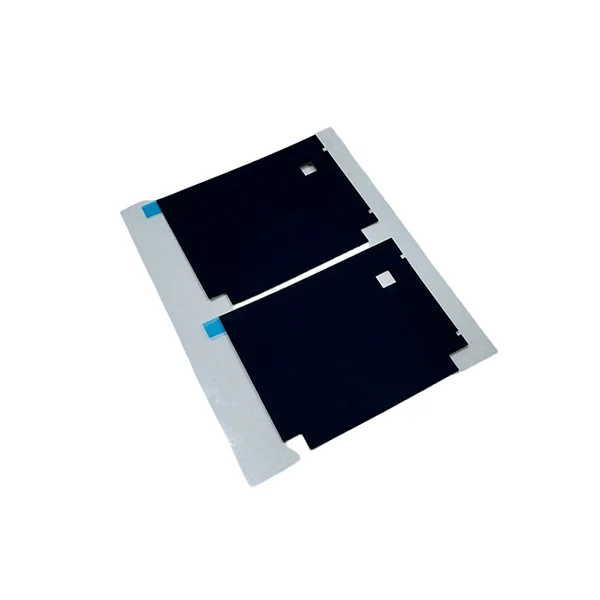

In the era of high-performance electronics, managing heat efficiently has become a core challenge. As devices become smaller yet more powerful, the demand for superior thermal interface materials continues to rise. The ultra-high thermal conductivity graphene thermal pad, represented by products like ZS-GM-GSM graphene thermal sheet, is redefining how industries handle heat dissipation and performance optimization. Zesong, a high quality graphene thermal sheet manufacturer, will share the features of ultra-high thermal conductivity graphene thermal pad for sale.

Understanding the Role of Graphene Thermal Pads in Heat Dissipation

Graphene thermal pads are engineered materials designed to transfer and spread heat evenly across components. Unlike conventional silicone or ceramic pads, graphene-based thermal sheets utilize the exceptional physical and thermal properties of graphene—known for its thermal conductivity exceeding 1500 W/m·K.

The ZS-GM-GSM graphene thermal pad efficiently conducts heat in both planar directions, reducing hot spots and enhancing the operational stability of electronic devices. This two-dimensional heat spreading capability not only lowers component temperatures but also extends the service life of sensitive chips and modules.

Key Features of Ultra-High Thermal Conductivity Graphene Thermal Pads

The performance of ultra-high thermal conductivity graphene thermal pads is defined by several advanced characteristics that distinguish them from traditional thermal materials:

-

Exceptional Thermal Conductivity:

With superior heat transfer capability, graphene pads rapidly dissipate heat from high-power chips to heat sinks or enclosures, maintaining low junction temperatures even under heavy workloads. -

Lightweight and Flexible:

Despite their robust performance, these pads are lightweight and easy to handle, suitable for compact electronic assemblies without adding mechanical stress. -

Low Thermal Resistance:

The low interfacial thermal resistance ensures minimal temperature difference between the heat source and the dissipation surface, improving overall system efficiency. -

Consistent Thermal Shielding:

Graphene sheets not only conduct heat but also shield heat-sensitive components, preventing overheating and maintaining balanced thermal distribution.

Graphene Thermal Sheet Applications Across Industries

The graphene thermal sheet like ZS-GM-GSM has found wide acceptance in diverse sectors due to its versatility and reliability. Its unique combination of high conductivity, flexibility, and ease of integration makes it indispensable in modern electronics.

1. Consumer Electronics and Computing Devices

Applications include notebook PCs, flat panel displays, LED boards, and PC memory modules. Leading brands such as Sony, Dell, Samsung, and ZTE leverage graphene pads to maintain device performance while ensuring thermal stability under compact housing designs.

2. Display and Projection Systems

For PDPs, LCD TVs, and projectors, graphene thermal materials efficiently dissipate heat from large panels and light sources, helping to maintain color accuracy and prolong screen life.

3. Communication Equipment

In network systems, routers, and mobile devices, graphene thermal pads reduce overheating in processors and transceivers, supporting continuous operation and data transmission stability.

4. Medical and Industrial Equipment

High-precision instruments and medical imaging systems demand stable thermal environments. Graphene thermal sheets ensure that critical components remain within optimal temperature ranges for accurate and safe operation.

How Ultra-High Conductivity Graphene Thermal Pads Improve Device Performance

The integration of ultra-high thermal conductivity graphene thermal pads goes beyond simple heat transfer—it fundamentally transforms how heat management is approached in design.

-

Improved Component Reliability:

By maintaining consistent temperatures, graphene pads minimize thermal stress and degradation in sensitive components such as CPUs, MPUs, and power modules. -

Energy Efficiency and Noise Reduction:

Efficient heat dissipation reduces the need for active cooling (like fans), leading to lower energy consumption and quieter operation. -

Compact Design Flexibility:

Engineers can design thinner and more compact systems without compromising performance, a key advantage in today’s mobile and wearable electronics. -

Extended Product Lifespan:

With reduced thermal cycling and stable operation, electronic products exhibit longer life cycles and fewer failures over time.

Science Behind Graphene’s Thermal Conductivity

Graphene’s exceptional thermal behavior stems from its atomic structure—a single layer of carbon atoms arranged in a hexagonal lattice. This configuration allows electrons and phonons to move freely with minimal resistance, resulting in extraordinary heat transfer efficiency.

When integrated into thermal pads like ZS-GM-GSM, graphene layers work together to create multi-directional thermal pathways, dispersing heat horizontally and vertically. This property is particularly beneficial in multilayer circuit boards and densely packed devices, where uniform heat spreading is crucial.

Future Trends in Graphene-Based Thermal Interface Materials

As device performance pushes physical limits, graphene thermal management materials are expected to play a more central role in next-generation electronics. Ongoing developments aim to further enhance thermal conductivity, electrical insulation, and mechanical durability.

Emerging research focuses on hybrid graphene composites—combining graphene with polymers or ceramics—to optimize flexibility, cost, and scalability. These innovations will expand the application scope to include electric vehicles, 5G base stations, and high-performance computing.

Why Choose ZS-GM-GSM Graphene Thermal Sheet for Your Application

The ZS-GM-GSM graphene thermal pad is a comprehensive solution for manufacturers and engineers seeking reliable, efficient, and lightweight heat management materials. Its dual-directional heat conduction, low resistance, and compatibility with a wide range of substrates make it ideal for:

-

LED lighting systems

-

Communication base stations

-

Laptops and gaming devices

-

Automotive electronics

-

Power modules and converters

Whether in consumer electronics or industrial-grade equipment, this thermal sheet ensures stable operation and optimized performance under thermal stress.

Conclusion

The ultra-high thermal conductivity graphene thermal pad marks a technological leap in thermal interface materials. As electronics continue to evolve toward higher performance and compact designs, graphene-based solutions like ZS-GM-GSM offer unmatched efficiency, reliability, and versatility.

By integrating these advanced thermal materials, manufacturers can not only solve heat dissipation challenges but also unlock new levels of product durability and energy efficiency—paving the way for the next generation of smarter, cooler, and longer-lasting electronic devices.

-

-

AuthorPosts

- You must be logged in to reply to this topic.